Vital Insights right into Transformer Oil Regeneration for Operators

Vital Insights right into Transformer Oil Regeneration for Operators

Blog Article

Exactly How Regenerated Transformer Oil Prolongs Transformer Lifespan

The role of transformer oil is essential in guaranteeing the dependability and durability of transformers, offering as both an insulator and coolant. Regrowed transformer oil offers a compelling remedy to boost these functions by effectively eliminating unsafe impurities that jeopardize performance.

Relevance of Transformer Oil

Transformer oil plays a crucial function in the reliable procedure of electrical transformers. It largely acts as a protecting tool, guaranteeing and protecting against electric discharges that elements run securely under high voltage problems. The oil's dielectric residential or commercial properties are essential to maintaining the integrity of the transformer, as they minimize the threat of failures that might bring about tragic incidents or costly downtimes.

Along with its insulating abilities, transformer oil additionally operates as a coolant. As transformers run, they produce warm that should be dissipated to avoid getting too hot and subsequent damage. The oil circulates within the transformer, moving and taking in warmth far from vital parts, therefore keeping ideal operating temperatures.

Furthermore, transformer oil serves as a barrier against moisture and contaminants, which can compromise the efficiency and durability of the transformer. Its chemical residential properties help in neutralizing acids and various other byproducts that may create over time, adding to the general health of the electric system.

Benefits of Regenerated Oil

Furthermore, regenerated transformer oil has a lower degree of impurities, consisting of fragments and pollutants that can degrade performance. This purity not just enhances the oil's thermal conductivity yet also extends the operational lifespan of transformers by decreasing overheating threats. The improved thermal security of regenerated oil guarantees regular efficiency even under high operating temperature levels, which is crucial for keeping transformer performance.

An additional advantage is its environmental impact. Regenerated oil promotes sustainability by lowering waste and the requirement for new oil manufacturing, thereby decreasing the carbon impact associated with transformer maintenance. Transformer Oil Regeneration Process. In addition, the durability of restored oil translates to reduced maintenance expenses gradually, as fewer oil modifications and less regular tools downtime are needed.

Process of Oil Regeneration

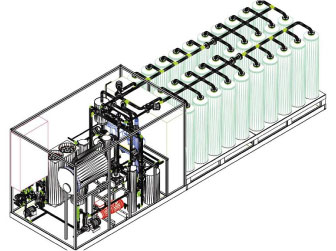

The regrowth of transformer oil entails an organized process created to restore the oil's initial residential or commercial properties and enhance its performance. This process typically begins with the elimination of the utilized oil from the transformer, which is then subjected to numerous purification techniques.

The very first step in the regeneration procedure is the filtration, where from this source solid impurities such as sludge, dust, and metal particles are eliminated. This is typically complied with by vacuum cleaner distillation, which aids to remove moisture and unstable compounds, therefore boosting the oil's dielectric strength.

Effect On Transformer Performance

Restoring the buildings of regenerated transformer oil significantly influences the general performance of transformers. Improved dielectric toughness is just one of the most essential benefits, as it enables for much better insulation and minimizes the chance of electrical break down. This renovation results in a more stable operation under high voltage problems, ultimately leading to boosted efficiency.

In addition, the removal of contaminants and destruction products throughout the regrowth process reduces the danger of overheating. Cleaner oil facilitates far better warmth dissipation, which is important for keeping optimum operating temperatures. Therefore, the thermal efficiency of the transformer is improved, permitting greater loads without endangering integrity.

Additionally, the chemical security of regenerated oil makes sure extended operational life. It resists oxidation and deterioration, decreasing the frequency of maintenance interventions and oil replacement. This security not just adds to improved efficiency but likewise straightens with sustainability objectives by decreasing waste.

Future of Transformer Upkeep

As innovations in modern technology proceed to improve the landscape of electrical design, the future of transformer upkeep is positioned for significant makeover. The combination of clever modern technologies, such as IoT sensors and anticipating analytics, makes it possible for real-time tracking of transformer health, boosting the capability to preemptively resolve problems before they intensify right into significant failings. This positive method not only takes full advantage of operational efficiency however also prolongs the lifespan of transformers.

In addition, the application of synthetic knowledge (AI) in data analysis enables even more exact mistake detection and diagnosis. By leveraging maker learning formulas, upkeep teams can recognize patterns in operational data that human analysts may overlook, resulting in even more informed decision-making.

Furthermore, the adoption of green practices, including the use of regenerated transformer oil, is established to redefine maintenance methods. This sustainable approach not only decreases ecological impact however additionally enhances the total health and wellness of the transformer.

Lastly, the change in the direction of automation in upkeep procedures is expected to improve procedures, decrease downtime, and reduced prices. As these technologies continue to evolve, the future of transformer upkeep will definitely become a lot more effective, trustworthy, and sustainable, guaranteeing the integrity of you can try these out essential electrical facilities.

Conclusion

The use of regenerated transformer oil substantially enhances the operational long life of transformers. Inevitably, the adoption of regrowed oil stands for a crucial development in transformer upkeep, making sure ideal efficiency and sustainability in the management of electrical framework.

The function of transformer oil is essential in making sure the dependability and longevity of transformers, serving as both an insulator and coolant.Transformer oil plays an essential function in the reliable procedure of electrical transformers. Restored oil promotes sustainability by minimizing waste and the demand for brand-new oil manufacturing, therefore reducing the carbon impact linked with transformer maintenance.Recovering the properties of regenerated transformer oil considerably affects the general performance of transformers.The use of regenerated transformer oil dramatically improves the operational longevity of transformers.

Report this page